Do you want to set up a biomass pyrolysis plant? It can be an intimidating process and there is certainly a lot of research that needs to be done before getting started. With the right knowledge and preparation, however, this enterprise could prove both profitable and beneficial for the environment, since it produces sustainable energy sources from organic matter such as wood, plants or crops.

Discover all the steps necessary for setting up your very own biomass pyrolysis plant – from initial planning to obtaining permits and licenses; from arranging top design teams to navigating environmental regulations – so that you’re armed with all the know-how needed for success.

1. Researching and planning for a biomass pyrolysis plant

Spending adequate time researching pyrolysis plants and the legal requirements for setting one up in a particular area is key. Begin by learning about the different types of biomass pyrolysis plants, such as fast pyrolysis for bio-oil and slow pyrolysis for biomass gasification. Also research the particular biomass resources available in the chosen location.

2. Obtaining permits and licenses

After conducting the necessary research and creating a plan for the plant, it’s time to apply for the permits and licenses that are required for the project. Depending on the location, this can include obtaining an environmental permit, business license and operating permit.

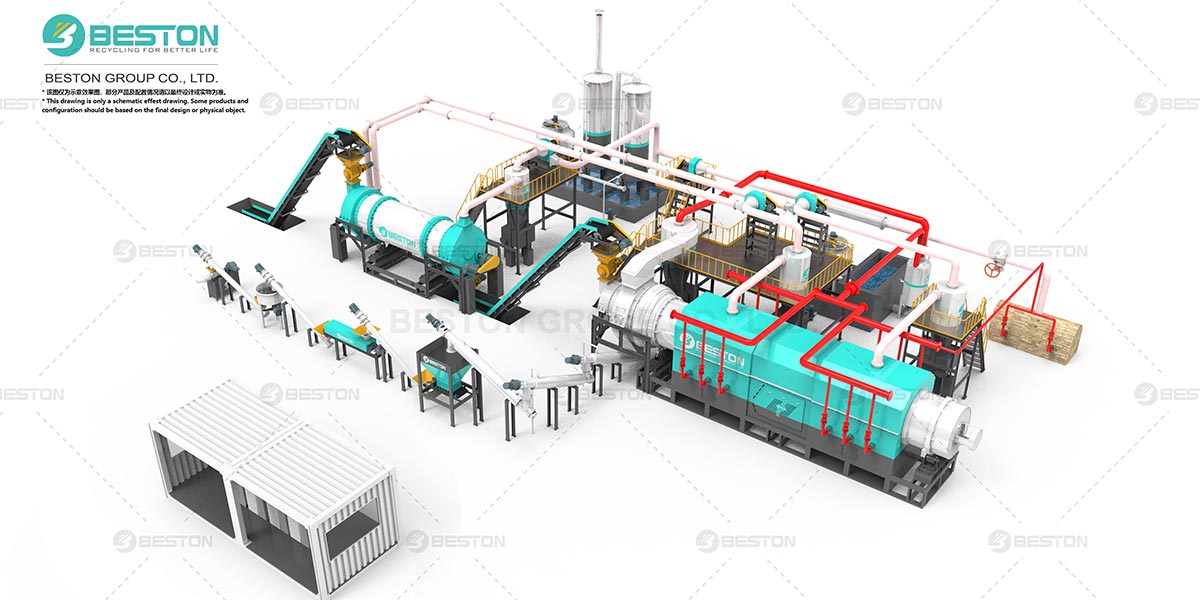

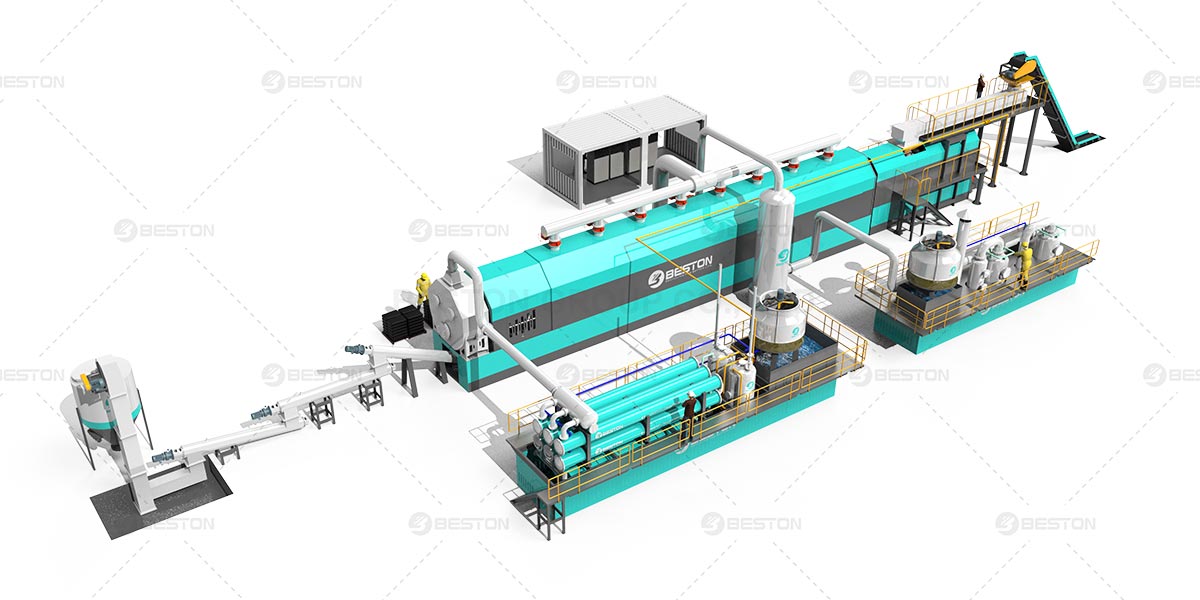

3. Designing the plant layout

The next step is to hire a team of qualified engineers and professionals to design the plant layout and technical specifications. The plant should include the necessary biochar maker for sale, such as an oxygen-free reactor, a condenser, a gasifier and a scrubber.

4. Arranging top design, engineering and construction teams

In order for the plant to run smoothly, it’s important to hire the best available design, engineering and construction teams. Look for professionals with experience in handling biomass pyrolysis projects and make sure they’re up-to-date on all the latest advancements in this field.

5. Navigating environmental regulations

Since this is a green energy project, there are certain environmental regulations which must be taken into consideration. Make sure that the plant meets all the necessary requirements in terms of emissions and resource use. Pay special attention to local zoning regulations, as these can vary from place to place.

6. Setting up the equipment for production

Once the design phase is complete and all the necessary permits and licenses acquired, the next step is to set up the equipment. This includes connecting it to the grid and making sure it is up and running properly. Make sure to also install safety equipment and have a maintenance plan in place. Get the charcoal making machine price 2023 here.

7. Establishing operational procedures and safety protocols

This step includes training staff on how to operate the equipment safely and setting up internal processes to ensure that the plant is running smoothly and efficiently.

8. Monitoring performance and maintenance of the plant

The last step is to monitor the performance of the plant, ensuring that it meets all its targets. Regular maintenance should also be conducted in order to maintain the integrity of the equipment and prevent any unforeseen incidents. This also includes monitoring emissions from the biochar production units and taking measures to minimize these as much as possible.

By following these steps, you’ll be well on your way to setting up a successful biomass pyrolysis plant and producing clean, sustainable energy.