As the world becomes increasingly more conscientious about environmental impact, it’s no surprise that the waste tyre pyrolysis industry is on the rise. Pyrolysis is a process that thermally decomposes organic material in the absence of oxygen, yielding combustible fuel gases, liquid hydrocarbons, tarry residues and carbon char. While there are many companies who offer continuous waste tyre pyrolysis plant for sale, not all of them are created equal. So how do you choose the right plant for your business? Here are a few things to consider.

How Does It Work?

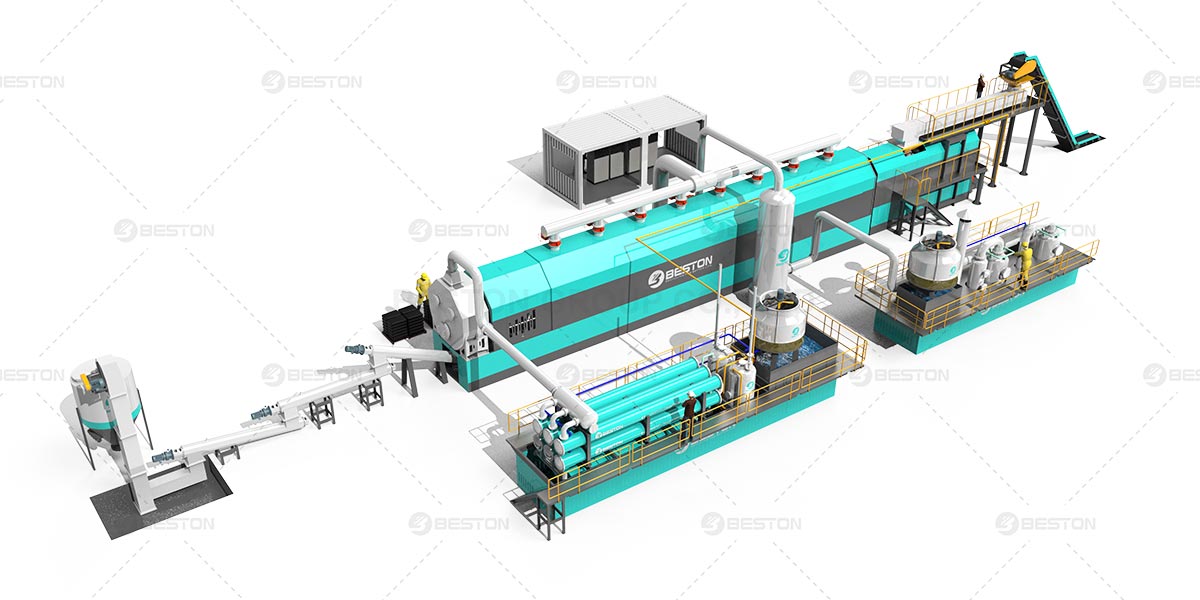

A waste tyre pyrolysis plant is a machine that converts waste tyre into fuel oil. The process of tyre pyrolysis is a thermochemical reaction in which the large molecules of the tyre are broken down into smaller molecules. This process can be carried out in either a batch or a continuous reactor. In a batch reactor, the tyres are placed in the reactor and heated for a set period of time before being cooled and removed. In a continuous reactor, the tyres are fed into the reactor and continually heated for as long as the process is running. The main advantage is that it is more efficient and can process larger quantities of tyres.

The Benefits Of Using a Continuous Waste Tyre Pyrolysis Plant

The pyrolysis plant for sale operates by heating the tyres in an oxygen-free environment. This causes the tyres to break down into their component parts, which can then be used to create new products. One of the main benefits is that it is much more efficient than traditional incineration plants. It also produces fewer emissions, making it more environmentally friendly. In addition, the plant can be used to generate electricity, which can be used to power homes and businesses.

Key Features to Consider

There are a few key features you should look for when purchasing a waste tyre pyrolysis plant. First and foremost, the plant should be able to process multiple tyres simultaneously. This will help increase the overall efficiency of the plant and minimize downtime. The plant should also be equipped with an automatic feeding system to reduce labor costs and improve safety. Get tire pyrolysis plant cost here.

You’d also want a plant that generates a high yield of pyrolysis oil. This will help maximize profits and make the process more sustainable. Finally, the plant should be backed by a good warranty to ensure that you are getting a quality product that will last for many years.

How Much Will It Cost to Purchase And Install One?

The cost of purchasing and installing a continuous waste tyre pyrolysis plant will vary depending on the size and capacity of the plant. The installation costs will also vary depending on the location and complexity of the project. However, once the plant is up and running, it should be able to generate revenue through the sale of pyrolysis products such as fuel oil and carbon black. In addition, the plant can help reduce the environmental impact of waste tyres by recycling them into valuable products instead of simply disposing of them in landfill sites. More information about Beston Group here.