The production of egg trays has been modified multiple times over the years. In the past, the production of these was primarily a manual process. People would break waste paper into pulp first and then pour the liquid material into molds, heat it until it dried, and would set it out in the sun to remove the moisture. This was a slow and demanding process, but modern innovations have made this very easy. Without it, we would not be able to process and sell the millions of egg tarys that people buy on a regular basis. If you have one egg tray machine, you may want to make a daily report of your production levels. This is how you can get this done, as well as request a report from the egg tray machine manufacturers about the features and benefits of their machines.

How Does Paper Egg Tray Machine Work

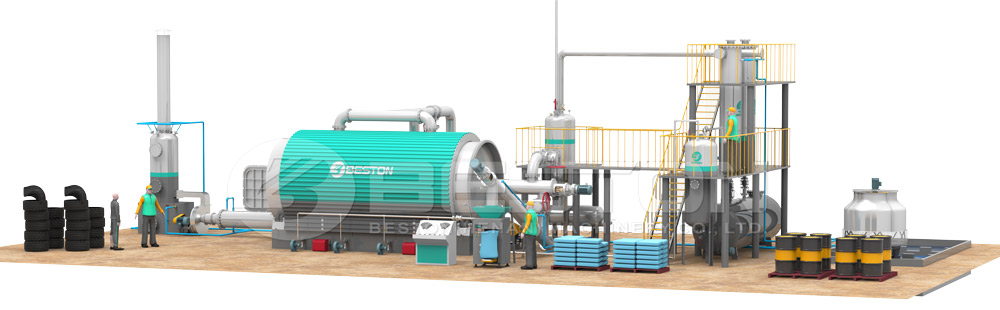

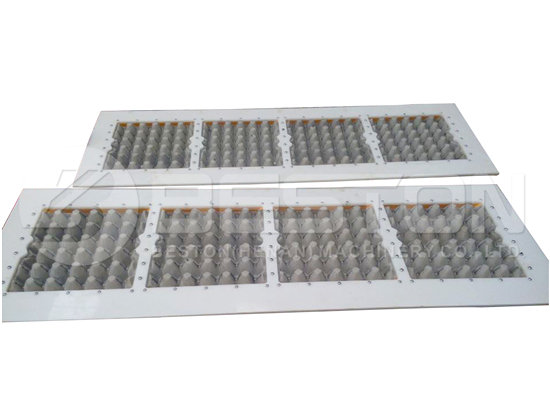

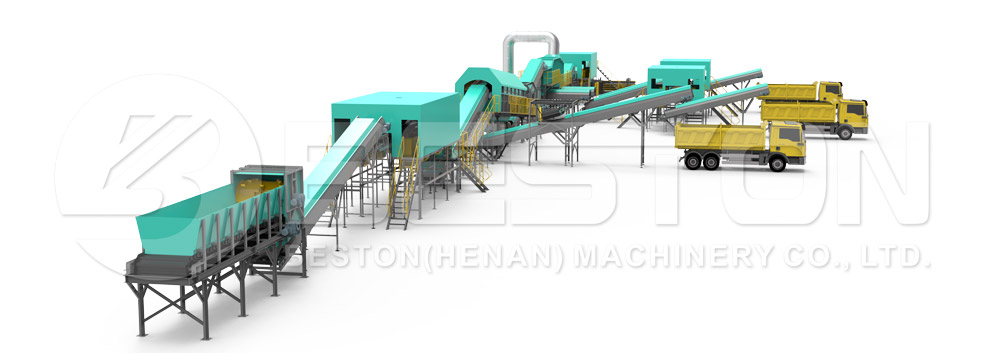

Despite producing such a small item, this process does require several different machines. They all work together to eventually produce the egg trays that we see in the supermarket. In many cases, the material that is used is a form of pulp that comes from recycled organic materials. This is cleaned, processed, and eventually poured into the pulp forming machine and the molds within it. Subsequent to this, it will go through a drying production line. This is a series of heaters through which the egg trays will pass under, allowing them to solidify. If it is a fully automated system, these will then go to another conveyor belt where people can stack off the egg trays.

What Type Of Reports Should You Make?

If you decide to make a report, it should be about the overall production levels of each of these machines. For example, if you have one that is semiautomatic, and one that is fully automated, those reports will differ in regard to overall production and speed. You may make manual reports by keeping a record of how many egg trays are produced. You can also keep track of the slurry of pulp that you are using on a daily basis. This information can be used to determine whether or not your egg tray machine is functioning at maximum capacity. More models can be found: https://bestoneggtraymachine.com/egg-tray-making-machine/.

Can You Get Reports From The Manufacturer?

The reports that you can get from manufacturers will include all of the specific details about how they work. For example, they will tell you what the production capacity will be, the mold quantity, and the total amount of power that it will deliver. Electricity consumption will also be noted as well as how many people will be needed to run it successfully. Fuel consumption, materials consumption, and many other factors will also be detailed.

Will It Take Long To Find These Companies?

Locating businesses that produce egg tray making machines is simple. That is because there are so many companies that create them. They are designed in slightly different ways but they all perform the same process. The largest ones will take up a substantial amount of room. Therefore, you need to have a facility where they can be housed, yet still leave room for others that may be doing work in the same building. You can find these businesses by searching online, or in your local paper, and then request this information.

Egg tray making machines are very advanced today. If you are able to get an automatic one, you can produce thousands of egg trays every hour. Consider the labor force that you have available that may be necessary to run these machines. Finally, get the prices from the different companies that offer this service and choose one that is affordable and has a high level of production. Also, a qualified supplier will offer you a great egg tray manufacturing business plan.