Egg trays play a major role in the protection of eggs during transportation and storage. Egg trays are produced by pulp molding machines that convert waste pulp into the packaging material. Although the egg tray making process is relatively simple, this machinery is primarily used to make the trays in huge quantities in a short period. Purchasing an egg tray making machine can help increase your profits, but only if you settle for the right machine. That being said, here are several tips and features to consider when looking at egg tray machine for sale.

The level automation goes without saying to be the first aspect to look at. The latest iterations of egg tray machines are pretty efficient and capable of saving up to 50 percent electricity compared to other ways of making egg trays. It’s also important to look at the space needed for the equipment. IF the machinery features a multilayer dryer, it will save a lot of space, which can save you a lot when space comes at a premium.

All your egg trays should be the same. This is not just a sign of quality, but an indicator of the egg tray machine’s efficiency. As such, ensure that the device you pick is capable of making egg trays with the same weight and dimensions each and every time. A standard egg tray production line features 4 varying parts, which include pulping, pulp molding machine, drying as well as packing. Below is a video of the Beston egg tray making machine in India.

During the initial step, which is pulping, a slurry is created by smashing wastepaper. An array of chemicals is added to the pulp so as to get the right consistency. In terms of raw materials, the slurry can be created using craft papers, recycled papers, old newspapers, cartons, cardboard, etc.

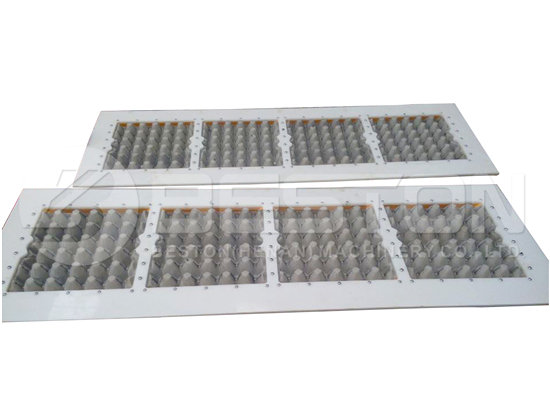

Once the slurry has reached the required consistency, it’s time for the next stage, which is molding. During this process, the air compressors and the paper pulp moulding machine are utilized to produce wet egg trays. Varying types of molds can be utilized at this stage to make varying kinds of trays, including apple trays, egg trays, etc.

When the wet trays are made, the next step is to dry them using a conveyor. Both automated and manual drying lines are accessible for the process, and the selection depends on your budget and also the amount of production you wish. During this stage, excess water is squeezed out of the wet trays, and the final result is processed and dried. The final stage is packing, whereby a vast number of trays are squeezed together to cut down the volume and make a package that is easy to transport.

And there you have it, a few important aspects to keep in mind when shopping for egg tray machines. You are running a business, and so, it is important to get machinery that really matches your needs. If you are uncertain about the best one, do not hesitate to consult experts in the industry. And Beston Machinery is a great choice.