The plastic-to-fuel business is an innovative solution addressing two critical challenges of the modern era: managing plastic waste and meeting the growing demand for alternative energy sources. This guide provides a professional roadmap to developing a successful plastic-to-fuel business, covering essential aspects such as market analysis, operational strategies, financial planning, and sustainability.

1. Industry Overview

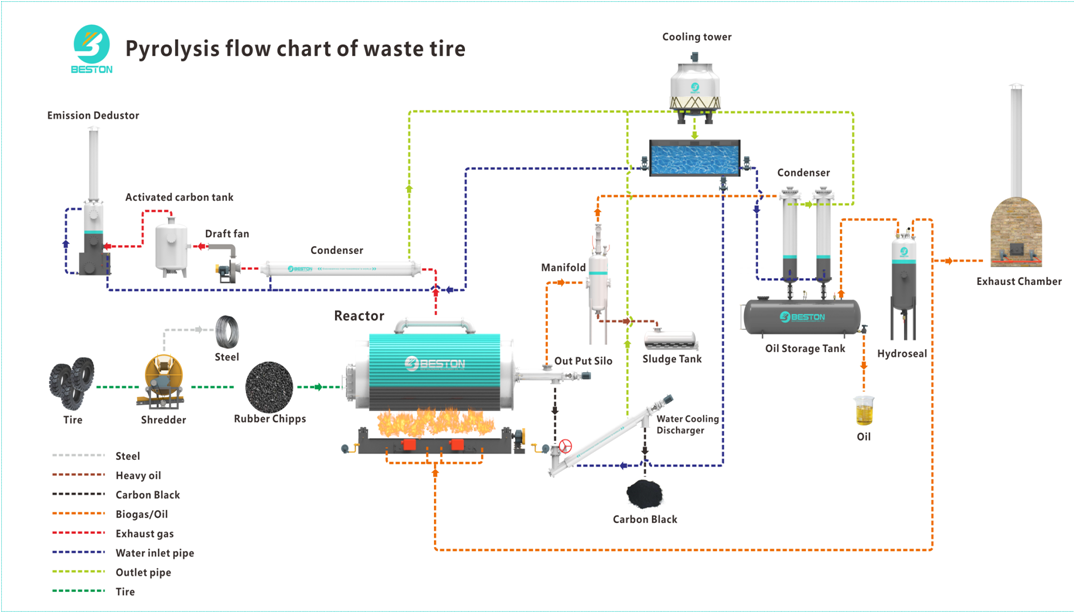

The global concern over plastic waste has reached unprecedented levels, with over 300 million tons of plastic produced annually and a significant fraction improperly disposed of. The plastic to fuel process, powered by pyrolysis technology, offers a dual benefit: reducing landfill burden and producing valuable fuel products like diesel, gasoline, and industrial-grade oil.

Market Drivers:

- Increasing governmental regulations on plastic disposal.

- Rising demand for cleaner, alternative energy sources.

- Public awareness of sustainability and circular economy principles.

2. Business Model Outline

A. Value Proposition

The business transforms waste into a revenue-generating product while contributing to environmental preservation. This aligns with global trends favoring sustainable business practices.

B. Target Market

- Municipal Waste Management Companies: Providing a plastic to oil solution for their plastic disposal challenges.

- Industrial Fuel Consumers: Supplying cost-effective, high-quality fuel.

- Renewable Energy Markets: Positioning the business within the clean energy value chain.

C. Revenue Streams

- Sale of refined fuel products.

- Fees for plastic waste processing services.

- By-products like carbon black and syngas for supplementary income.

3. Operational Plan

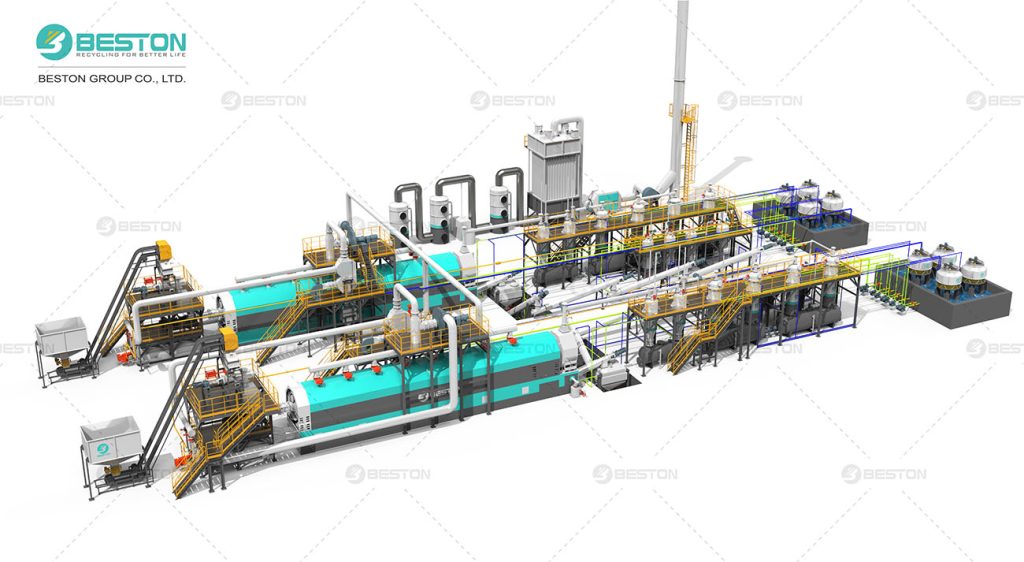

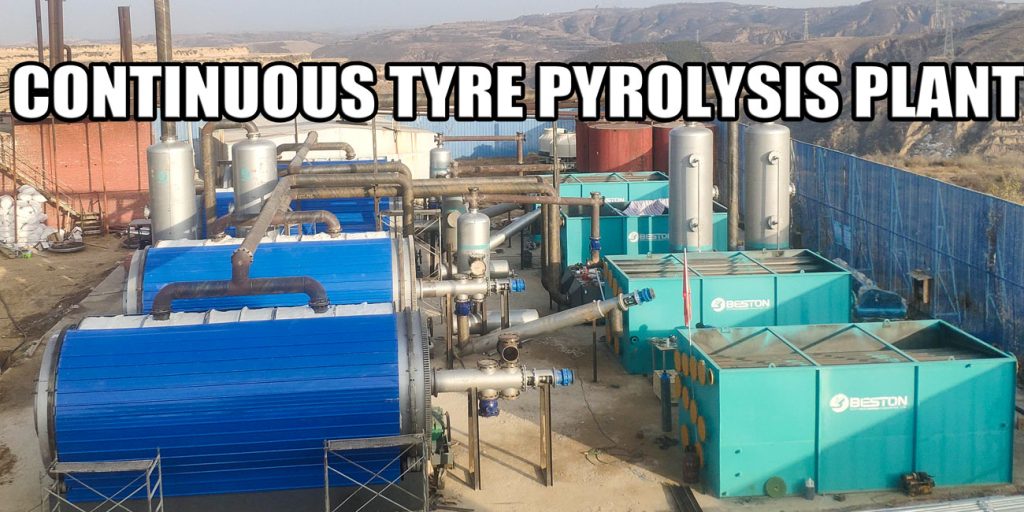

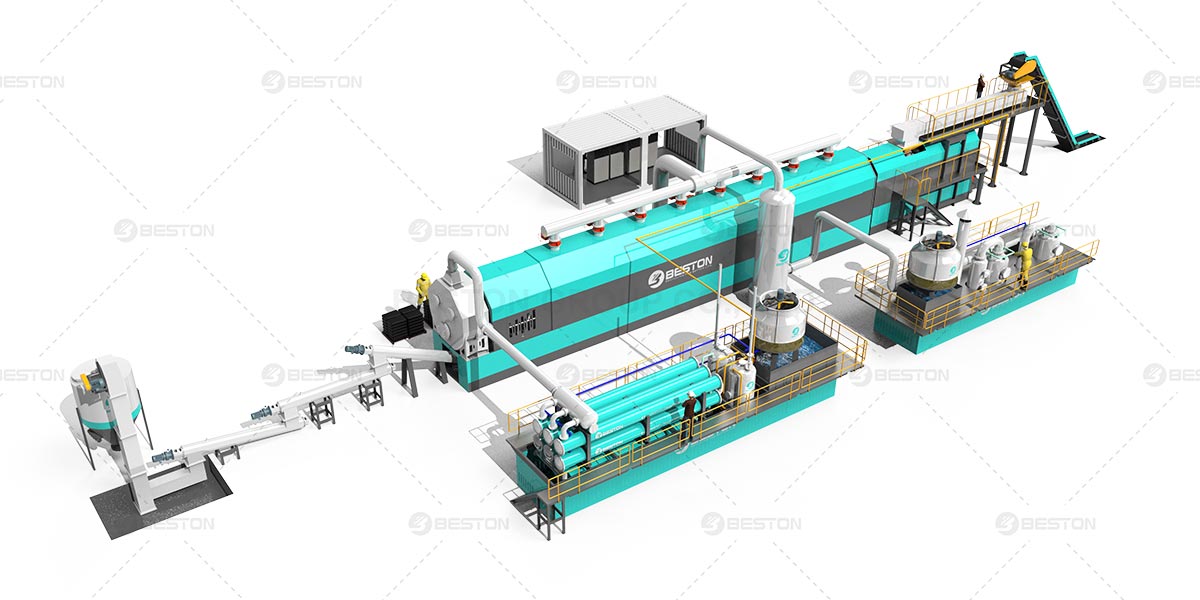

A. Technology and Equipment

The cornerstone of the business is the pyrolysis machine, which heats plastic waste in an oxygen-free environment to break it into fuel. Key considerations for choosing equipment:

- Capacity: Scalable options ranging from small batch units to continuous systems.

- Energy Efficiency: Machines with syngas recycling for reduced operational costs.

- Compliance: Adherence to environmental regulations.

B. Facility Setup

- Location: Proximity to waste sources and fuel markets.

- Infrastructure: Storage for raw materials and by-products, safety systems, and waste management facilities.

- Workforce: Skilled operators for machine handling and maintenance.

4. Financial Planning

A. Investment Requirements

- Equipment Purchase: Depending on scale, pyrolysis systems range from $50,000 to $500,000.

- Facility Construction: Costs vary based on location and capacity.

- Operational Budget: Includes labor, utilities, and transportation.

B. Revenue Projections

Each ton of plastic yields approximately 600 liters of fuel. With fuel prices averaging $0.8 to $1.5 per liter, the revenue potential per ton ranges from $480 to $900.

C. ROI Calculation

Average payback period: 12-24 months depending on operational scale and market conditions.

5. Sustainability and Compliance

Environmental and legal compliance is vital for long-term success. Key steps include:

- Acquiring licenses for waste processing and fuel production.

- Ensuring emissions meet local standards.

- Implementing waste heat recovery and water recycling systems.

6. Risk Management

A. Market Risks

Fluctuations in oil prices can impact profitability. Mitigation: Diversify revenue streams by selling by-products like carbon black.

B. Operational Risks

Technical failures can disrupt production. Mitigation: Invest in high-quality equipment and robust maintenance plans.

C. Regulatory Risks

Changes in legislation can affect operations. Mitigation: Maintain proactive engagement with regulatory bodies.

7. Marketing and Growth Strategies

A. Branding and Awareness

Position the business as a sustainability champion. Highlight environmental benefits in marketing campaigns to attract eco-conscious clients.

B. Partnerships

Collaborate with municipalities, waste management firms, and industrial clients for steady plastic waste supply and fuel demand. Maybe you can consider Beston Group – a leading pyrolysis plant supplier.

C. Expansion Plans

Start locally, then scale operations by adding processing units or entering new markets.

8. Conclusion: Seizing the Opportunity

The plastic-to-fuel business combines environmental stewardship with financial viability. A well-structured business plan, paired with innovative technology and sustainable practices, can unlock immense growth potential. As global efforts toward a circular economy intensify, investing in this transformative industry positions businesses for both economic success and lasting environmental impact.