Have you been considering buying some sort of paper molding machine? If you’ve been looking at machinery like this, you should look into buying a small paper egg tray making machine for sale. A machine like this can be a very wise investment. Here’s why.

You’ll Be Able To Recoup Your Investment Right Away

It won’t take very long for you to earn back the money you spent on your egg tray machine. It’s very easy to find vendors that are interested in purchasing egg trays; the demand for egg trays is huge. Because you should be able to produce large quantities of egg trays with the right machine, you’ll be able to start turning a profit in no time. Beston Machinery is one of the professional egg tray forming machine manufacturers.

Investing a machine like this is always going to be a risk. With that said, if you do decide to buy one of these machines, you’re not taking on a major risk. It shouldn’t be difficult for you to earn back every last cent that you have spent.

These Machines Can Work In A Range Of Spaces

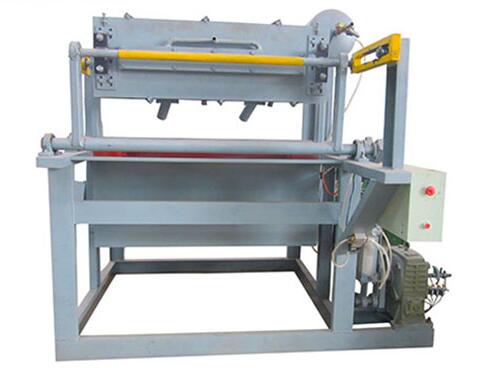

As the name implies, small egg machines don’t take up a lot of space. Because of this, it’s easy to find a place for one of these machines. They can work in a wide range of places.

There’s a very good chance that you can make room for a smaller machine like this. Look at the dimensions of a few egg machines. See if you can find a space for a smaller machine like this. The egg tray machinery price is competitive.

In some cases, smaller machines are less efficient than their larger counterparts. Thankfully, this isn’t an issue that egg tray machines have. These machines can product a large number of units per hour, even though they aren’t overly large.

The best machines are specifically designed with efficiency in mind. Because these machines work so well, people are easily able to meet their production quotas. In fact, if you choose the right egg tray plant, you may be able to increase your daily quotas.

There Are Plenty Of Options To Choose From

You shouldn’t have to make any major compromises if you choose to buy a machine that’s smaller. There are all kinds of options to choose from, from semi-automated machines to machines that require more user input.

If you’re interested in these machines, you should take a look at some of the choices available to you. You’ll probably be impressed when you see the range of choices available.

You should take your time and compare different choices so that you can find an option that appeals to you. There are so many quality machines on the market; it should be easy for you to find a product that’s worth investing in. Go to this page: http://eggtraymakingmachine.net/pulp-molding-machine/.

Are you trying to decide whether or not you would like to purchase a small egg tray machine? As you can see, a machine like this can be an excellent investment. You should start looking into buying one of these machines. Decide whether or not a machine like this would be a good fit for you.