Millions of tons of rubber and tyre waste are produced in the world every year. Most of these wastes are either burnt or used for filling the land. Burning emits harmful gases and creates threats to the environment. Pyrolysis technology emerged as a solution for decomposing plastic and tyre waste. Pyrolysis involves carbonaceous material’s thermal decomposition in an oxygen free environment. In this pyrolysis process, the pressure of the system is not restricted by the pressure of water vapour.

Application of pyrolysis helps to recover energy in rubber waste and tyre waste through chemical manipulation. Plastic recycling through pyrolysis process consists of several steps. All plastic waste needs to be sorted before putting it through the process. Mechanical recycling includes shredding of polymers and cryogenic grinding of plastics. Through rubber pyrolysis plant, the long chain molecules of polymer are cracked into smaller chains with the help of pressure and heat. It is similar to nature’s process where the earth breaks down carbon and produces oil. This natural process takes millions of years. The process of plastic pyrolysis produces mainly three products: Bio-oil, bio-char and syngas.

Bio-oil or tyre pyrolysis oil can be considered as a substitute for industrial diesel by oil distillation plant. Pyrolysis oil is also used in boilers, furnace, electric generators, diesel pumps, hot air and water generators, heaters, thermic fluids, and other equipment. Syngas is reused in waste tyre and rubber pyrolysis plant and the bio-char or carbon black is put to use in plastic and rubber industries and also in inks, paints etc. High calorific value biomass can only be pyrolised in order to generate bio-oil.

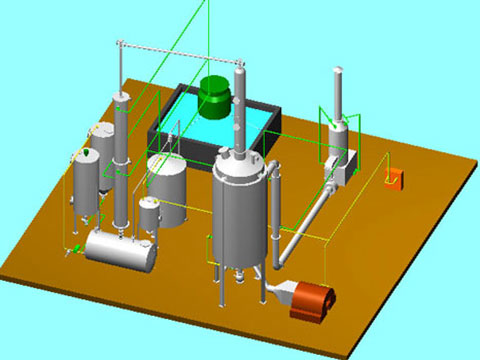

Tyre recycling through the waste tyre pyrolysis process involves heating of whole or shredded tyres without oxygen in a closed vessel reactor. Rubber polymers will break down and form smaller molecules. Vapourised smaller molecules are burnt further to produce bio-oil or pyrolysis oil. Solid, liquid and gaseous properties are derived from pyrolysis tyre process by the process conditions and feedstock used. A major issue related to waste rubber pyrolysis plant is the generation of the solid stream, which constitutes about 40% of the total output: https://www.bestongroup.com/pyrolysis-plant-for-sale/. Steel from solid stream is removed with the help of magnets, but the remaining bio-char has no value other than being a carbon fuel of lower grade.

Importance of waste tyre and rubber pyrolysis plant

The major advantage of the waste tyre pyrolysis plant is that it decomposes waste and produces valuable products. The pyrolysis process uses waste plastics and scarp tyre as biomass or feedstock. The pyrolysis process and output from this process are environment-friendly. Pyrolysis can produce synthetic diesel fuel and thereby the dependency on fossil fuels can be reduced. Bio-oil can be used in pharmaceuticals. Further research can yield technology that can convert bio-oil and in the future it may become a substitute fuel for car engines. Biochar or black carbon is considered as a useful fertiliser. Therefore, all products from pyrolysis process are different forms of renewable energy: https://www.bestongroup.com/tyre-to-fuel-recycling-plant/.