If you’ve heard the term biomass carbonization machine before and you’ve never really given much thought to its meaning, we’ll we’re here to shed some light and give you an eye opener. Biomass can be carbonized with new and improved waste treatment tech. Our article goes further into the biomass carbonization machines.

When we think of biomass, you should think of things such as shells, wood chips, plant stalks, rice husks and of course coconut shells. Simply put, these are readily used as the raw materials in the carbonization process in order to manufacture charcoal. The initial process makes full use of extreme high temperatures as well as vapors and gasses from the pyrolysis process along with concentrations of carbon and emissions of sulfur. If you have strong interest and wanna get fair charcoal making machine price, consult Beston.

After charcoal is manufactured from this process, or rather from the biomass carbonization machine, it is utilized within a series of industries. These include the food industry for making barbecue and it can also be used as the burning source for a hookah. Additionally, with further processing, the charcoal can also be converted into activated carbon. And it can even be used as a source of fertilizer in order to improve the current condition of your soil.

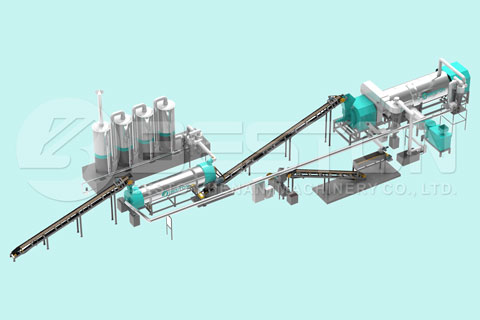

In order to convert a series of different sources into this particular resource, the leading manufacturer designed a state-of-the-art automatic charcoal machine. And it can also be used for the purpose of carbonizing solid waste along with the sludge from sewage. The system was designed in such a way to make use of a specially designed double layer which allows the bottom part of the machine to stay in contact with hot air. And while seemingly not important, think again because this particular feature goes on to effectively make use of the heat as it increases the overall efficiency.

The engineers also made sure that the plant utilized the two-step fire method. This just simply means that the heat produced from the plant is used along with any waste smoke to properly dry out the water from any biomass that will undergo processing. And the rate at which calorific fuel is used is more than 85% which means that those who purchase this plant only have to figure out how much it costs to undergo the carbonization process.

Learn more about this machine here: https://bestonasia.com/charcoal-making-machine-suppliers/.

As we conclude we have just looked at the biomass carbonization machine. And we have also looked at how it works along with some advantages of using this particular machine. Additionally, the plant has been designed to stay ahead of the environmental requirements.