Pyrolysis technology has emerged as one of the most popular technologies to recycle waste tyre and recover useful byproducts. Among other products, around half of the raw material that undergoes pyrolysis is recovered in the form of pyrolysis oil. The other products recovered from pyrolysis of waste tires include carbon black and steel wire.

While the pyrolysis oil recovered from the pyrolysis process can be used in its original form in various industries, it can also be further distilled into diesel oil by distillation system for tires oil and various other combinations of fuel that fetch a better price in the market. The distillation technology through which pyrolysis oil is distilled is known as reduced pressure distillation.

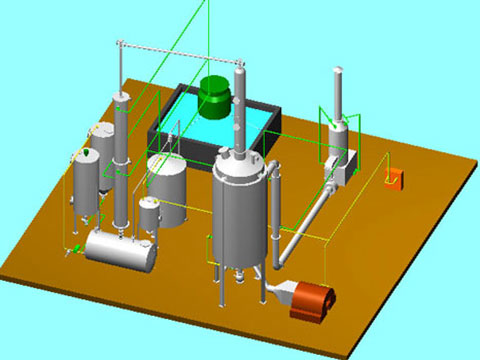

There are a number of distillation plant manufacturers for refining pyrolysis oil. Many of these plants have been optioned to distill or refine the pyrolysis oil under normal pressure as well as in vacuum. The plant is usually equipped with a heating system that helps in improving the safety of the plant and it also increases the efficiency of the plant. The distillation reactor is completely sealed to ensure that the distillation process is completed in an efficient manner and without any issues.

These plants can be operated as batch plants or as continuous operation plants. In the case of batch plants, the reactor needs to be fed with raw material and after distillation, the finished products are removed. In the case of continuous operation plants, the raw material is fed automatically and the finished materials are also removed automatically. There are a number of advantages of investing in a pyrolysis oil distillation plant.

One of the biggest advantages of investing in the distillation plant is that it is extremely easy to get high quality diesel oil through this distillation process. This diesel oil recovered from the pyrolysis oil distillation plant can be used in a variety of low speed engines and generators such as loading machine, road roller, digging machine and various other types of machines. This diesel is in high demand and sells for a good price on the market which means that it is a highly profitable business. You can get more pyrolysis oil from pyrolysis of scrap plastic. Find professional pyrolysis plant manufacturers now.

Another advantage of using this waste oil recycling plant is that it is environmentally friendly. These plants have an oil yield rate ranging from 80 to 90% which means that most of the raw material is converted into useful products at the end of the distillation process. The remaining material is released in the form of exhaust gases. However, the exhaust gases are recycled and the resulting gases released from the distillation plant for refining tires oil are completely free of pollutants. These plants are available in a variety of capacities ranging from 10 ton to 100 ton and above.

Overall, there are a number of advantages of converting pyrolysis oil into crude oil. The diesel oil recovered from this process is of high quality and can be used in a variety of machines. This process is quite profitable which means that there is a huge demand for such distillation plants all over the world. By investing in this business, you are not only helping in keeping the environment clean but are building a profitable business.