As thousand of trucks from all over the municipal area are brought into the solid waste disposal plant, it become obvious that any kind of recycling is going to require lots of sorting first. There is everything from broken furniture, to yard debris and rotten restaurant food to plastic bottles. Any attempt to refuse any of these materials will require that they be concentrated, each with their own kind since they will all end up in a different process. Plus, some, such as metals and much more valuable immediately than yard debris that is half dirt. Either way, it all has to be taken care of in one way or another, so sorting first is the key: https://www.bestongroup.es.

First Sorting Is By The Human Directing The Unloading

There are plenty of loads coming in, some from roofing contractors, landscapers, food processors, house builders, and others that are already mostly sorted into certain categories. Like everything from a roof maybe either old wood shingles or composition shingles and from the landscaper all brush, wood, weeds, and dirt. These are basically ready to enter the system once ground to a specific size to be processed.

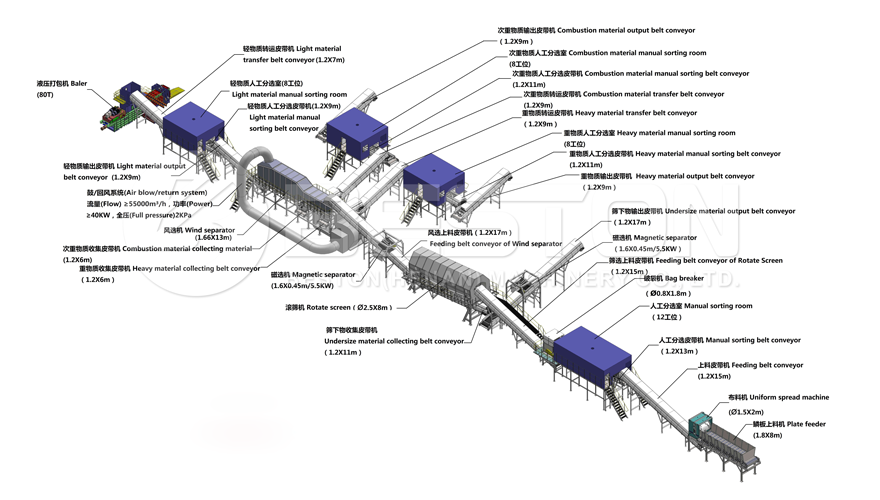

Garbage from home pick-up routes, on the other hand are full of dozens of varied types of waste, each with a different route to being recyclable. This type of waste will have to be sorted by machines to better concentrate the various materials. In an urban solid waste separation plant (planta de separacion de residuos solidos urbanos) there will be screen sorters that sort by size. That’s where the garbage is loaded into the top of the filter and each step has a smaller screen. At the very bottom will mostly be dirt and sand. At the top large items like furniture will end up and that may have to go to a grinder.

Another type of urban solid waste separation plant machine is one that uses centrifugal force to eject the lighter materials like plastics and let the heavy small materials like metals fall to the bottom. Each different sorter will separate out several different materials and sizes to be dealt with in a different manner.

Some things will get sorted out of one machine, then sent through a grinder to mince everything up to a smaller size. Then the ground material will again enter the sorter which can them separate the various materials again. In the end, it’s not uncommon for waste to go through several automatic garbage sorters before finally being piled up for processing into the pyrolysis machine (maquina de pirolisis).

The Pyrolysis Machine Needs A Fairly Consistent Feed

Most waste plants will end up with a constant and consistent feed material that is suitable for feeding into the pyrolysis reactor and be thermal-chemically reduced to basic ingredients like oils, gases, carbon, and ash.

Since the amount of oxygen is severely limited to avoid fire, the temperature can be over 450 C without causing a fire. This eliminates the problems of black toxic smoke and cancer causing air pollution from the waste plant: https://www.bestongroup.es/planta-de-clasificacion-de-residuos/.