Coconut shell charcoal briquettes making machines are very popular in many coastal areas across Europe, Africa, and Southeastern Asia. The larger machines can process up to 3 tons of coconuts an hour. The average machine has a life span of 5 to 8 years. You can get a free quote for different models of charcoal machines on official manufacturers websites. You can also contact approved suppliers via phone. If you are ordering from an overseas supplier, make sure you investigate any import charges you could be liable for.

In many coastal areas, coconut shells are a common type of organic waste, and they have high recycling value. A coconut shell charcoal briquettes making machine can covert the shells into charcoal via a carbonization process. The charcoal can then be processed further into activated carbon. Due to the fact that coconut shell charcoal has many uses, it can be sold for steady profits in the global marketplace. What’s more, a charcoal briquette machine can also be used to process wood, sawdust, straw, sewage sludge, and sawdust into different types of charcoals.

Advantages Of A High-Quality Coconut Shell Charcoal Briquettes Making Machine

1. Such a machine can be configured with an auto-feeder and water cooling slag-out to enable continuous operation around the clock.

2. Improved heat utilization design means that a machine consumes less energy.

3. Turns organic waste into valuable materials without causing any damage to the natural environment.

4. Produces high-quality end products. The carbon content of coconut shell charcoal exceeds 90%.

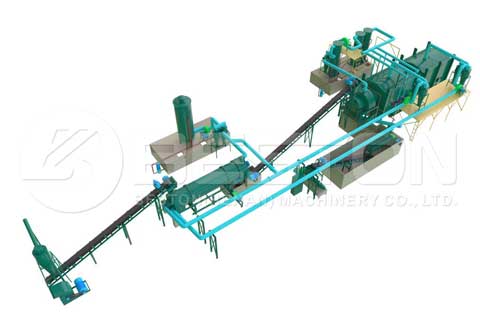

A typical coconut shell charcoal making machine is designed to ensure the heat produced when charcoal is been made is recycled and used for drying during the coconut shell charcoal making process. The two-layer structure ensures the exterior layer is used to dry the coconut shells and flash steam them, while the inner layer is used for carbonization. This heating method is referred to a “one fire two steps” in the industry. The method means machines have high energy efficiency ratings, meaning clients can enjoy reduced running costs.

Coconut shell charcoal has many different applications. For example, it is widely using in the catering industry to fuel barbeques and warming trays. In the agriculture industry is can be used to improve soil quality, which leads to enhanced grain output. It can be used as fuel in ceramic, steel and iron factory or mixed with clay to make construction bricks. To increase profits, many processing plants turn the coconut shell charcoal into activated carbon.

Unique Designs Features Of The Best Coconut Charcoal Machines

1. Strong protective outer cases to protect workers from exposure to high temperatures.

2. Standard control system used with the power section.

3. Professional smoke abatement, cooling system, and desulfurization systems to ensure safe exhaust gases.

4. Central control systems to separate the equipment and the operator for safety.

Wanna learn more information about the waste to energy plants projects like this in Malaysia? You can just search “waste to energy malaysia” through Google now.